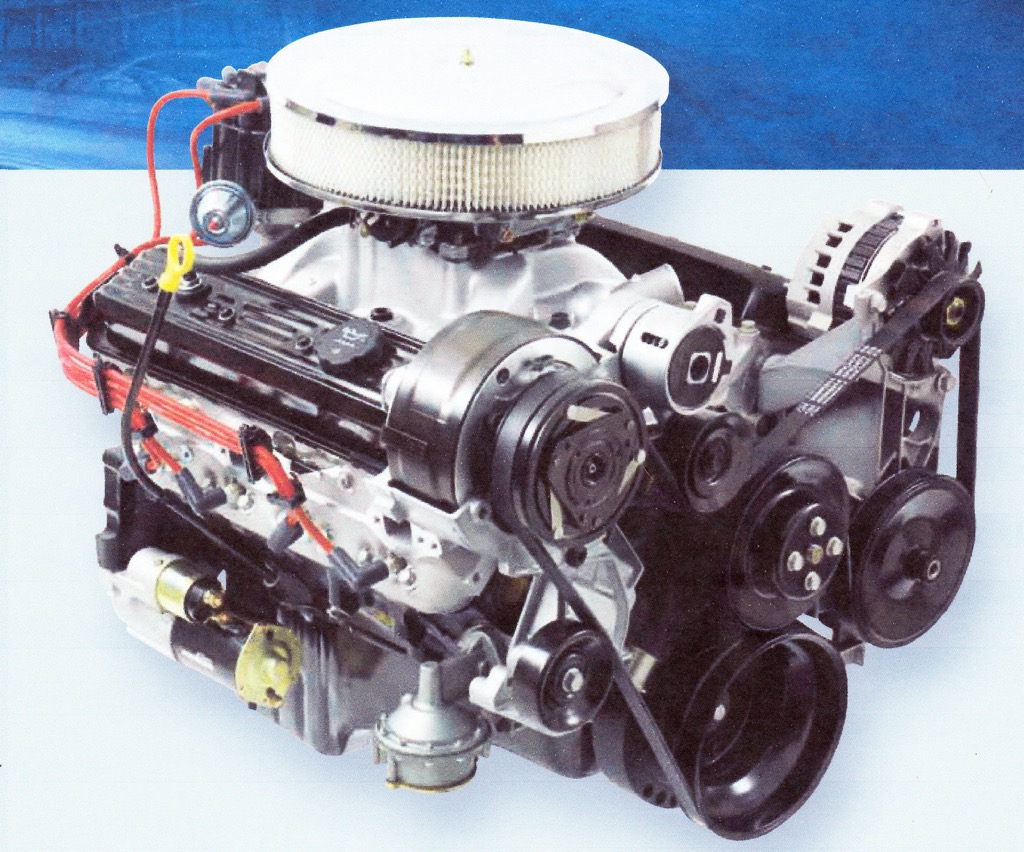

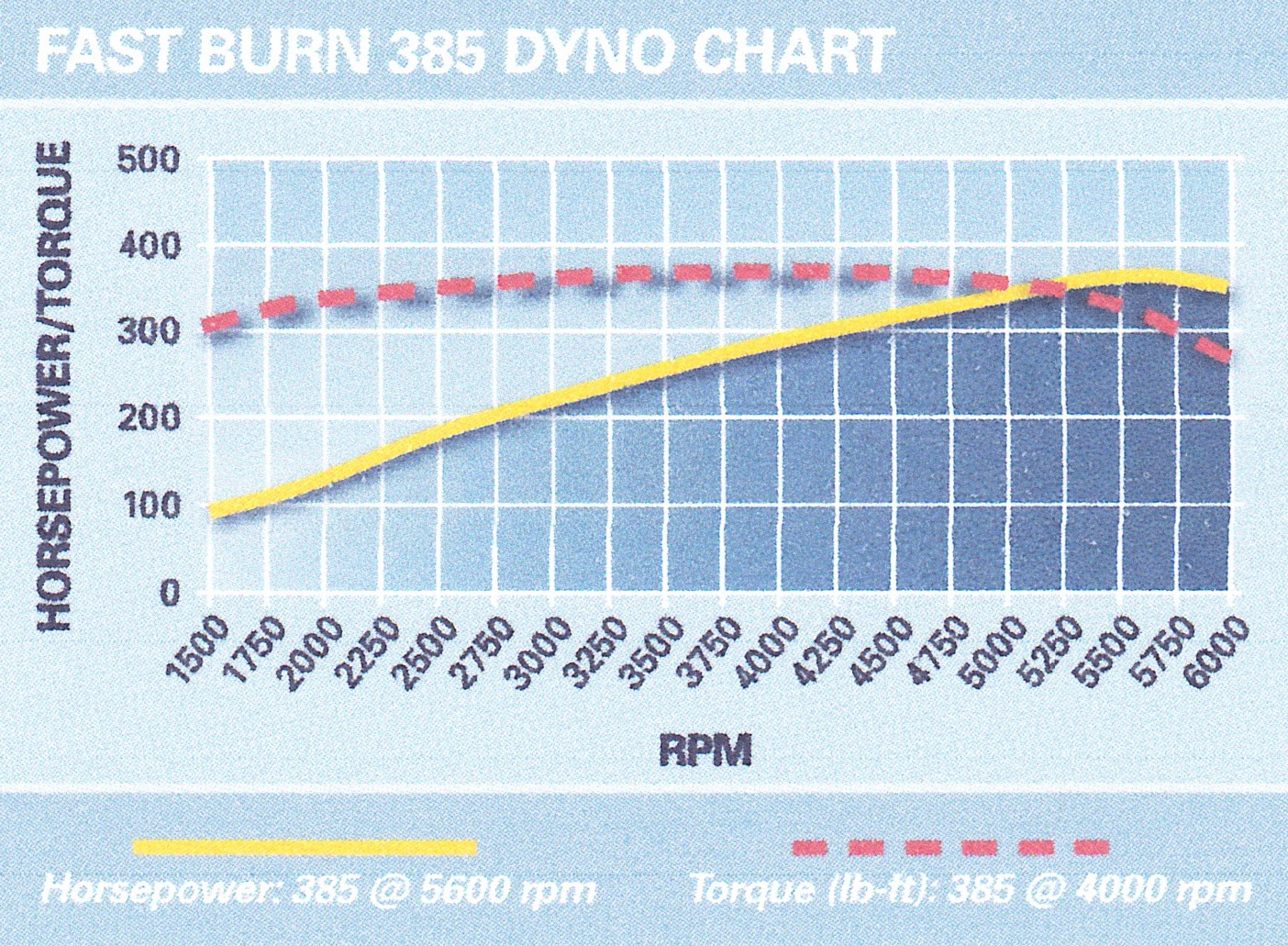

In 2008, a GM Performance Parts Fast Burn 385 crate engine was installed in my GTS Coupe. The objective was to try to make the new engine configuration look as close as possible to an original factory HQ 350 installation whilst replacing a tired engine with a 300+ HP package. The Fast Burn 385 is rated at 385 horsepower (287 Kw) and 385 ft lb (521Nm) of torque. The Fastburn engine has more power and torque than the 6.0 Ltr V8 used in a VF Commodore which is “only” rated at 260 Kw and 517 Nm. The Fastburn 385 engine uses;

-

a series 2 cast iron small block Chevy 350,

-

GM Performance Parts, aluminium large port “Fast Burn” cylinder heads

-

GM Performance Parts, aluminium high rise manifold

-

Holley 770 CFM vacuum secondary carburetor

A “Turn Key” version of the Fastburn 385 was chosen over the “base” short engine version as it included all new Delco accessories including carburetor, HEI distributor, power steering pump, 105 amp alternator and compact, R4 type air conditioning compressor. It also uses a single serpentine drive belt which produces a very compact accessory set up compared to the old triple pulley set up.

Installations problems / tips

-

the engine has exactly the same engine mounting points as a factory HQ 350

-

comes with a smaller diameter flex plate and matched, compact starter motor compared to factory HQ – and therefore the standard factory THM 400 converter will not bolt up to the smaller pitch centre diameter of the modern flex plate used on one-piece crank seal engines. Cannot attach the standard HQ 350 flex plate as it does not fit new crankshaft hub with one piece rear main seal.

-

high volume fuel pump supplied does not allow connection of factory fuel line. I replaced the high volume fuel pump with a standard SBC 350 AC pump with same fittings as factory HQ.

-

used factory fuel lines with the standard HQ-type fuel pump

-

The GM HEI distributor cap fouls the factory HQ 350 accelerator bracket. The connector block on HEI cap is the problem as it protrudes about 20mm on the passenger side of the cap. Can temporarily solve this problem by rotating the distributor 180 degrees and re configuring spark plug leads. Implemented a better solution using a billet Excel distributor with rev limiter that allows the distributor cap (rather than the whole assembly) to be rotated in 90 degree steps. For this application I rotated the cap 180 degrees to put the power connector on the opposite side to the accelerator linkage bracket. Engine documentation says that distributor vacuum is not required to be connected.

- The rev limiter is essential with this engine as demonstrated with the first full throttle take off with the run-in engine. Wheel spin in first gear allowed the engine to spin up past 6,000 rpm in the blink of an eye – potentially engine damaging. The distributor’s rev limiter is now set to a conservative 5,750 RPM.

-

Spark plug leads and GM lead holder hardware supplied in the Fastburn package will not fit over factory HQ exhaust manifolds – had to make a custom set of leads and use standard HQ lead brackets under rocker cover hold down screws. Standard HQ spark plug lead clips (x4) that bolt to the block just below the heads were used to properly feed the spark plug leads to the spark plugs. These mounting holes are also used to hold the factory HQ spark plug lead shields which have been installed

-

Bought a stainless steel fuel line set into carb from Rick’s 1st Gen Camaro supplies (in US)

-

Had to bend up and flare a custom 3/8 fuel line from factory HQ fuel filter to carb fuel lines

-

Supplied air cleaner element is too high – sourced a xx mm high element – still touches hood slightly but can’t go any thinner as air cleaner top hits top of carb

-

Needs a full 12 volt supply to HEI distributor – need to bypass the pink, in-line resistance wire normally feeding a factory HQ coil from the ignition switch

-

Power steering pump low pressure outlet pipe points upward (factory pipe points down). Temporary solution was to form a 3/8 bundy tube into a “U” shape to enable compact connection of low pressure hose. Problem ultimately solved by sourcing a new power steering pump reservoir / can with the low pressure fitting pointing down as per factory.

- Air conditioning system lines to compressor need to be re-routed to reach the compact R4 compressor now on the driver’s side of the engine as the factory compressor in on the LHS. After much trial and error and having bought too many incorrect fittings and an expensive A/C hose fitting crimping tool, the new hoses were installed and the system made operational!! Frigid Air again in summer !!

- Acceleration is astonishing but as somewhat expected, fuel consumption is well matched. Around town it averages 23 L/100km (12 mpg) with the highest ever achieved on a long run being 16.6 L/100km (17.8 mpg). The car really needs an overdrive gear to make long cruises less expensive.

[gallery_bank type=”images” format=”masonry” title=”true” desc=”false” responsive=”true” display=”all” sort_by=”sort_order” animation_effect=”bounce” album_title=”true” album_id=”38″]