The 350 “upgrade” began in January 2005 when an unmolested 1973 HQ Statesman 350 was found. The Statesman would provide all the parts necessary to upgrade the GTS to a “factory configuration” GTS 350.

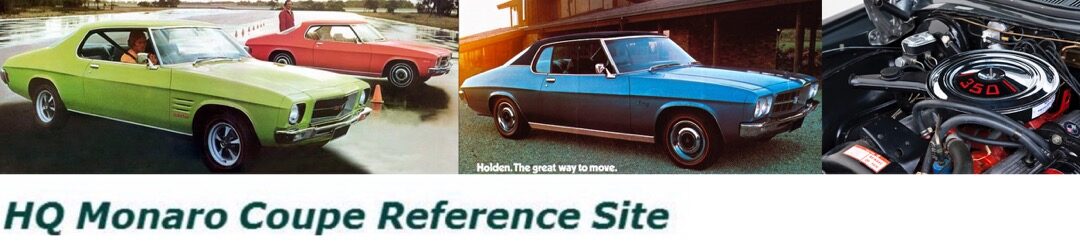

Pictures

- The donor Statesman 350 engine

- Original HQ 350 reference engine configuration

- The 350 V8 – T400 cleanup and transplant

- The finished job

My GTS would never be a genuine 81837 but it would provide a precise factory 350 configuration.

The Statesman had traveled 220,000Km with the engine and transmission showing no signs of being reconditioned. Cylinder pressures all measured above 150psi. The engine accessories were remarkably intact – all exhaust manifold heat shields, cable clips for the positive battery lead on LH head, fuel pump and sump, fuel vapour return tubing, ADR-27A emission control gear including a TVS switch in top radiator hose, Corvette rocker covers, chrome air cleaner and all the correct mounting brackets for the Frigidaire A6 compressor, Lucas 55A alternator and power steering pump.

The engine and transmission were thoroughly degreased. The welch plugs were removed and the water jackets cleaned out – the amount of sludge removed after 30 years of operation was incredible. The sump, inlet manifold, timing cover were removed and hot tanked back to bare metal. The motor was then painted in the original Holden “Rocket Red” paint. Contrary to popular belief, the HQ 350’s were not painted Chevy Orange. The original fuel pump and distributor were reused unchanged, except for a new set of Delco points. The Rochester Carb was stripped down, cleaned and reassembled with new gaskets and a new, metal, vacuum break actuator. The auto choke set up was adjusted to factory spec. New spark plugs and leads were installed. The old single exhaust system from the Statesman was temporarily installed to enable the car to be driven to an exhaust shop.

On first driving the car after installation of the engine and trans, it was evident that the transmission was slipping badly in 1st gear. It looked as if all the work was for nothing as a transmission removal and reconditioning looked inevitable. The oil level was double checked and was fine so clutch failure looked like the issue. On re-reading the Holden workshop manual it was realised that the oil level needs to be checked WITH the engine running. Another litre of Dexron goes in! The 1st gear slipping has now been eliminated. A full throttle take off produced copious wheel spin and then the biggest surprise of all – wheel spin changing into second gear !!

The car was then driven to Ringwood Performance Exhaust for a new dual exhaust system. They claimed they could make the engine pipes in one piece – with no welded joints, just as the original factory pipes were. Ringwood Exhaust had the original bending drawings so were able to make exact replicas of the original pipes. The Chevy engine with dual exhausts sounds very distinct and different from a 253 / 308. A new exhaust heat valve (still available in the US) was installed that closes off the RHS exhaust outlet and forces the hot exhaust gas back through the inlet manifold to increase cold start fuel vaporisation. These valves are almost always missing from surviving 350s but they work fine and are fully open once the engine reaches operating temperature.

When the engine was finally dyno-tuned, the Qjet throttle body was found to be warped from overtightening its 4 mounting bolts over the years and required straightening. The throttle shafts needed to be re-bushed. Interestingly, the original factory spec primary jets and secondary metering rods were still in place. Both were changed during the dyno runs to achieve optimal power / economy. The original Delco points-distributor needed a replacement shaft due to wear of the original. The camshaft was rated as moderately worn but still good enough..

When the engine was finally dyno-tuned, the Qjet throttle body was found to be warped from overtightening its 4 mounting bolts over the years and required straightening. The throttle shafts needed to be re-bushed. Interestingly, the original factory spec primary jets and secondary metering rods were still in place. Both were changed during the dyno runs to achieve optimal power / economy. The original Delco points-distributor needed a replacement shaft due to wear of the original. The camshaft was rated as moderately worn but still good enough.

In November 2006, the GTS successfully completed a 2,100 Km round trip to the Monaro Nationals that were held in Loxton SA.